Need a DIY project? Here’s how to modify a 3D printer to make food or ceramics – new research

While the pandemic has restricted us from doing many activities we like, household hobbies such as DIY, baking and crafts have become more popular. Now there’s a way to combine all of these skills to create something entirely new. What you will need, however, is a 3D printer.

3D printers will print anything made of plastic, quickly and in any shape you like. But there’s a lot they cannot do. You couldn’t 3D-print pasta shaped like your children’s favourite cartoon characters or make a pizza shaped like the logo of your football team – until now, that is. Our new research paper, published in Data in Brief, shows a simple way to re-engineer your 3D printer to create items made out of food or clay.

During the last few years, 3D printing has come out of science fiction, research laboratories and tech companies and landed within the reach of enthusiast hobbyists. That’s because the printers are becoming cheaper and easier to use. Several competing brands sell 3D printer assembly kits online for less than £300 and its feed materials, plastic filaments, for less than £20 a kilogram.

While 3D printers may sound like very complicated, futuristic machines, it’s actually quite easy to understand how they work. The software for controlling a 3D printer takes a 3D image and slices it into many 2D (flat) images. The printer, as instructed by the software, then “draws” these flat images on the top of one another using molten plastic as the ink. This pile of thin slices becomes a solid object.

To make this happen, an electric motor in the printer pushes the plastic filament into a nozzle, which is heated at more than 200°C – melting the filament and pushing it out of the nozzle. This printing head, made up of the nozzle and the motor, can move around in all three directions (length, breadth and height) because it is mounted on a separate setup of motors, pullies, belts and screws for each of these directions. A 3D printer is nothing but the printing head, the movement setup, and a circuit board that controls these two and talks to the computer.

How to print food

Imagine gifting your friends customised cakes or coffee mugs printed out of clay. For these, you need a 3D printer that uses pastes, gels, or slurry-type materials as the feedstock instead of the plastic filament. The gels or pastes could be clay or something edible that you want to make a shape out of, for example, jelly, dough, soft cheese and jam.

Such a printer could have an empty “cartridge” to fill your feedstock and a print head that can “print” out of this cartridge. Such printers have already been available for years. However, these are generally more expensive than £1,000. But who needs them when you can make one at home and have fun doing it?

Our new research shows exactly how you can modify a cheap, plastic 3D printer to print gels and pastes. The key is replacing the print head that melts plastic with a “syringe pump”, which is a setup that holds a common plastic injection syringe and squeezes the feed material when required. The plastic syringe itself works as the printer cartridge. The syringe pump is just a plastic frame that holds the syringe. The motor can be used to rotate a screw that pushes a nut down, pressing the syringe plunger with it and forcing the material out of the syringe needle.

But how do you make the syringe pump? That’s where it gets interesting. You can 3D-print it in plastic before you modify the printer. Our scientific paper, which is free to read, contains all the 3D images you require to print all the parts and the exact steps to assemble them.

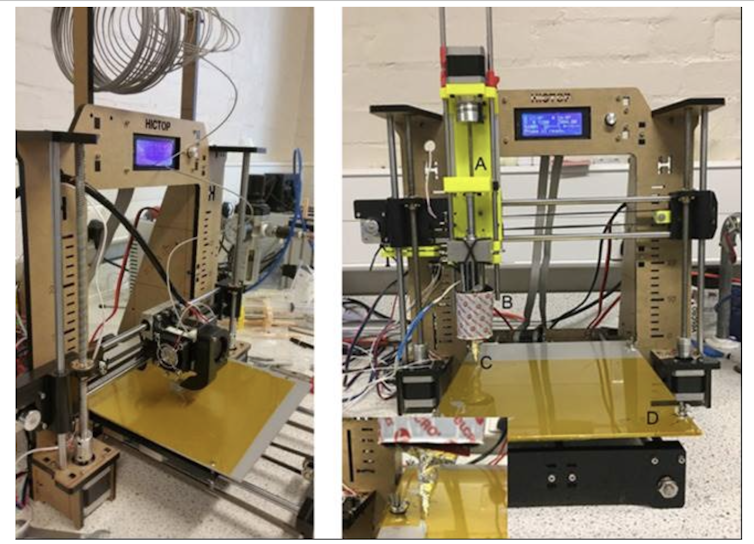

You can see the printer before and after the modification in the picture below:

Author provided

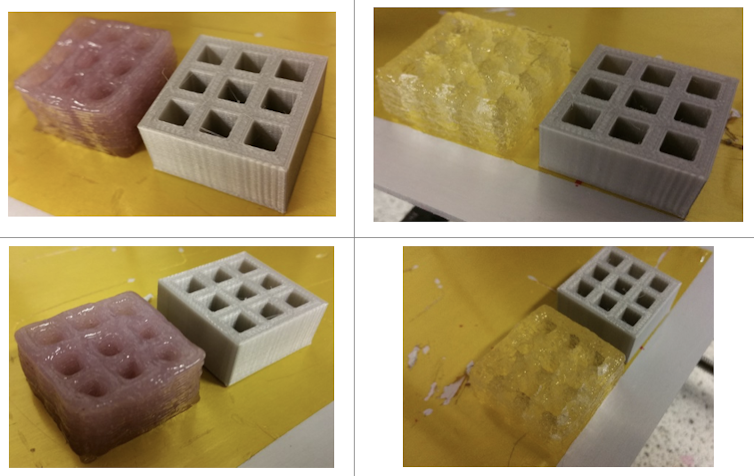

The syringe can be filled with almost anything semi-solid and 3D-print it the same way you would print using a plastic printer. As an example, we 3D-printed two different types of food-grade gums, shown in the image below:

Author provided

Once you modify your printer, you can also switch back to the old print head easily if you want to print out of plastic again. Have fun!![]()

Written by Saumil Vadodaria, Research Fellow, Chemical Engineering, University of Birmingham and republished from The Conversation under a Creative Commons license.