The UK government has set an ambitious target to expand nuclear power generation capacity from 6.9GW to 24GW by 2050.

This is part of a broader strategy to improve energy security while meeting net zero emissions goals. Small modular reactors (SMRs) are expected to play a vital role in achieving these aims.

As part of this drive, GE Hitachi Nuclear Energy (GEH) has been selected by the Department for Energy Security and Net Zero for a £33.6 million UK Future Nuclear Enabling Fund grant. The grant will support GEH’s BWRX-300 boiling water small modular reactor design and accelerate its deployment readiness in the UK market.

What are Small Modular Reactors? An Engineering Perspective

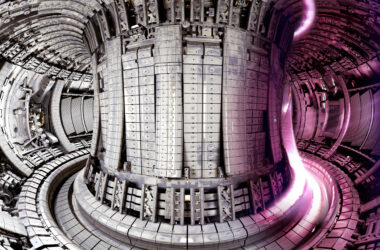

Small modular reactors (SMRs) are advanced nuclear fission reactors with power capacities of up to 300 megawatts electric (MWe) per module. As the name suggests, modularity and compact size are defining features of SMR designs.

Engineering SMRs for smaller outputs poses unique challenges compared to traditional large-scale nuclear plants. Factors like neutron economy, thermal efficiency, and physical containment must be optimized on a reduced scale. Meeting safety and economic goals also requires engineering innovations in modular fabrication, transportation, and onsite assembly.

A key restriction SMR engineers face is neutron leakage from the smaller reactor core. More neutrons escape without undergoing fission reactions, meaning less fuel can be utilized. Enriching uranium content counteracts this issue but worsens nuclear proliferation risks. An active research area is novel core geometries that maximize neutron reflection back into the energy.

Working fluid choice and thermal transfer mechanisms also differ in SMRs. Alongside standard light water designs, alternatives like liquid metals, molten salts, and gases offer pros and cons that engineers must balance. Passive cooling systems relying on convection and gravity provide safety advantages but pose complex modelling problems around heat flux surfaces.

Constructing an SMR facility from prefabricated units rather than onsite builds offers economic benefits but has logistical implications. Issues range from optimizing modular factory workflows to managing radiation levels in transport and meeting nuclear regulatory standards on assembly practices.

Ongoing engineering efforts on materials, manufacturing processes, modular integration, and licensing procedures aim to make SMRs a viable source of clean energy. Realizing their full potential depends on solving interdisciplinary challenges around scaled-down reactor physics, safety assurance, and practical deployment.

Details on the BWRX-300 Design

The BWRX-300 hopes to build momentum across existing SMR technology using proven fuel and plant components from existing reactor designs.

Its simplified boiling water reactor has an electrical capacity of 300MWe. Key features include:

- 60-year operating lifespan

- Refuelling is needed every 12-24 months

- Passive cooling isolation condenser for safety

- 90% less plant layout volume versus large plants

- 24-36 month construction time per module

The idea is that by basing the product on licensed reactor technology with established supply chains, GEH aims to offer a safe, affordable SMR solution.

Attracting private investment has been a historic challenge for new nuclear projects in the UK. The full-scale 3.2GW Hinkley Point C plant relied partially on public funding, while plans for other large-scale plants have stalled over funding issues.

Modular reactors provide opportunities to reduce upfront capital costs sustainably. However, the BWRX-300 faces competition from alternative SMR proposals in the UK market. Five other reactor designers have been shortlisted alongside GEH for government SMR funding contracts to be awarded next year.

GEH appears confident in the deliverability of the BWRX-300 based on progress made in recent American projects. It has an agreement to supply Ontario Power Generation with a 300MWe unit in Canada by 2028. The company also cooperates with the Tennessee Valley Authority and others to invest in the BWRX-300’s design standardization.

GE already has a significant business presence across the UK energy industry. The company operates 11 local sites, employing 2,500 staff. Recent partnerships reinforce GE Hitachi’s ties with UK nuclear supply chains and regulators.

This includes a steel supply memorandum with Sheffield Forgemasters and an agreement with Jacobs Engineering to provide regulatory support. GEH aims to continue developing relationships with UK companies to maximize domestic sourcing opportunities from BWRX-300 construction and servicing needs.

The selection for FNEF funding cements GEH’s ambition to use the BWRX-300 to assist the UK in hitting its decarbonization and energy security goals. The company is poised to submit a strong proposition in the next phase of Great Britain’s SMR competition.

The UK is embarking on a significant expansion of nuclear capacity over the next 25+ years, in which small modular reactors will likely play a key role alongside large plants. The GE Hitachi BWRX-300 represents a promising option to contribute clean electricity through its simplified and cost-effective modular boiling water design backed by an established industry player.

Subject to the successful completion of regulatory assessments and local supply chain integration, the 300MWe reactors could help the UK reach its increased nuclear capacity targets in time to curb emissions. This would bolster climate goals while buffering national energy supply needs for the long term

TLDR:

- UK aims to expand nuclear power capacity from 7GW to 24GW by 2050 to improve energy security and meet climate goals.

- Small modular reactors (SMRs) are expected to play a vital role, with over 80 designs under development globally.

- GE Hitachi’s BWRX-300 compact boiling water reactor was selected for £33.6 million in UK government funding.

- 300MWe output, 60-year lifespan, passive cooling for safety, 24-36 month modular construction

- UK context: attracting private investment is complex and faces competition from other SMR designs

- However, progress on Canadian and US projects gives confidence in BWRX-300’s deliverability.

- GE Hitachi has a long history in the UK, working with local companies to build a supply chain.

- Successful deployment of the BWRX-300 fleet could assist the UK in hitting nuclear capacity targets for emissions reduction.