A UK startup is charging ahead to decarbonize regional and domestic flights with an innovative drop-in electric engine replacement.

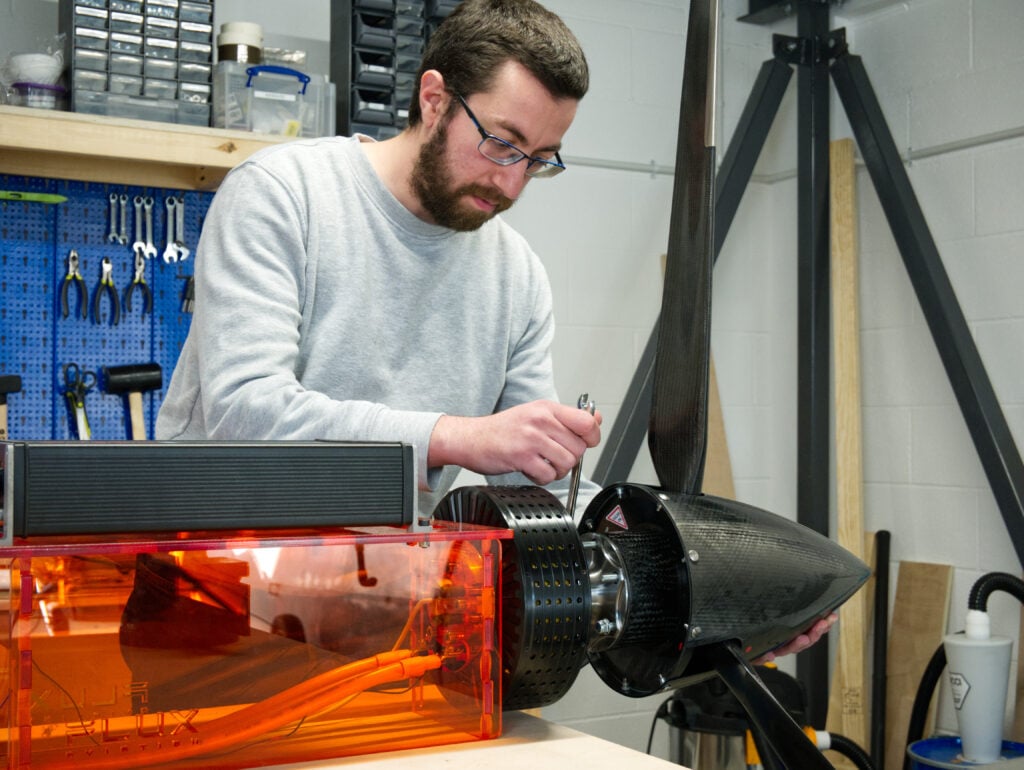

After receiving recent grant funding, Flux Aviation has accelerated the prototype development of its 75kW battery-powered powertrain system.

During engineering studies, Flux Aviation founders Neofytos Dimitriou and Radovan Gallo met and launched the aerospace startup in 2021 with ambitious sustainability goals. Seeking to phase out loud, dirty and expensive combustion engines, their electric powertrain promises to act as a replacement capable of slashing operating costs and emissions.

The prototype is designed explicitly for the aviation industry; Flux’s integrated electric motor and battery system produces zero emissions at the point of use. The power-dense, 100KW electric drivetrain slots into existing airframes as a substitute for standard piston and turboprop engines.

According to Gallo, optimal efficiency comes from proprietary battery management algorithms and motor control software. Intelligent systems match performance to the application by adjusting parameters in real time during operation. This enables compatibility across various aircraft, from 2-seater training planes to 50-passenger regional carriers.

Compared to traditional engines running on fossil fuels, the electric motor solution consumes over 30% less energy while emitting no greenhouse gases. Noise measurements indicate volume reductions nearing 50%—a welcome change for communities near airfields.

Recent funding from Get It Made, an advocate for UK manufacturing, has enabled Flux Aviation to iterate designs using diverse materials and techniques. The grant supports hands-on R&D critical for pushing boundaries in emerging electric flight.

Flux sees flight schools and aeroclubs embracing electric planes first as battery-powered motors slash fuel costs and emissions without sacrificing performance and eliminate the hassle of maintenance on complex combustion systems. The key is that swapping electric motors from traditional engines in existing two and four-seat trainers allows rapid adoption. Flying schools will only take planes out of commission for short upgrades. The company hopes these small planes will help Flux gain industry credentials to scale up later.

Flux remains on schedule for initial test flights of its electric retrofit by late 2023. Safety regulators are currently reviewing their protocols to ensure quality standards.

The company sits at the forefront of a massive shift towards electric and sustainable aviation. Legacy combustion engines face surging expenses and tightening emissions laws. One projection estimates a $178 billion market for electric urban aircraft in the coming decade.

We hope that long-term electric propulsion allows for safer, cleaner, cheaper air travel as battery energy density rises exponentially.

TLDR

- UK startup Flux Aviation is developing electric powertrains to replace loud, dirty combustion aircraft engines

- Their integrated battery & motor system reduces emissions and costs by over 30%

- Recent funding has accelerated prototype development and testing

- Flux is starting with small training aircraft, ultimately aiming to scale up to regional airliners

- Electric propulsion paired with new materials and designs promises a revolution in affordable, sustainable aviation